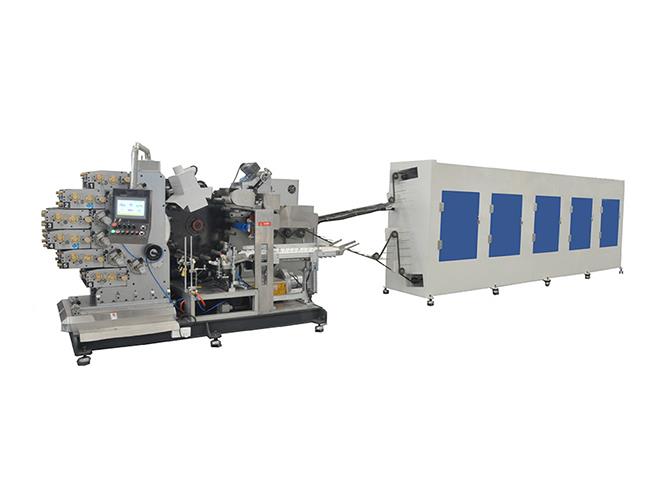

Brief Introduction

Two layer extruder & cutting machine adopts the multi-screw extrusion, and the surface of the tube produced is more delicate. It is widely used in the packaging of cosmetics, facial cleanser, hand cream and other cream products.

Features

1、Two-layer extrusion tube can reduce material cost.(using : Pearl + PE/PE + Pigment)

2、The temperature controllers of different materials can be controlled individually. In this way, we can find out the best running condition on the materials both in running fluency and dissolubility.

3、The surface of co-extrusion tubes made by two-layer machine is more glossy than the surface of mono-layer tubes.

4、Using the same material on two-layer co-extrusion can increase the water-resistance and anti-peneteration of the materials for about 20-30% (using: PE+ Pigment.Inner: recycled material.)

Main Specifications

|

Screw Diameter (inner): |

φ45mm, 15HP |

|

Screw Diameter (outer): |

φ40mm, 10HP |

|

Screw L/D Ratio (inner): |

32/1 |

|

Screw L/D Ratio (outer): |

32/1 |

|

Screw Type : |

Full flight |

|

Water Consumption: |

40L/min . 5-10C |

|

Power Consumption : |

66kw |

|

Extrusion Linear Speed : |

100pcs/min |

|

Cutting Speed: |

100pcs/min |

|

Tube Dia Range : |

φ19-60mm |

|

Machine Size : |

6500*4000*2100mm |

|

Total New Weight : |

approx.5200kg |