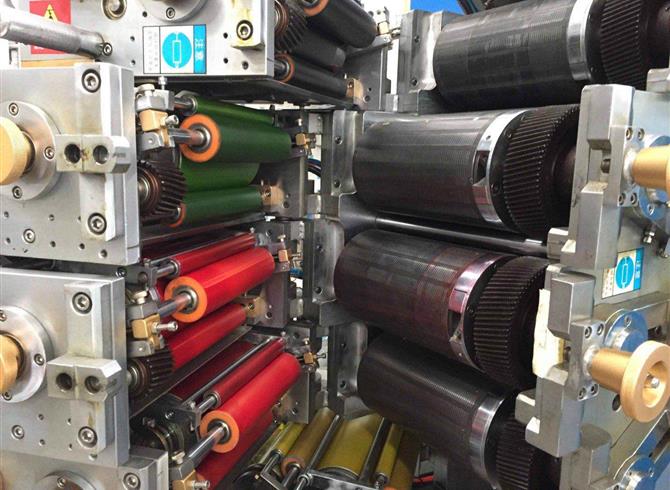

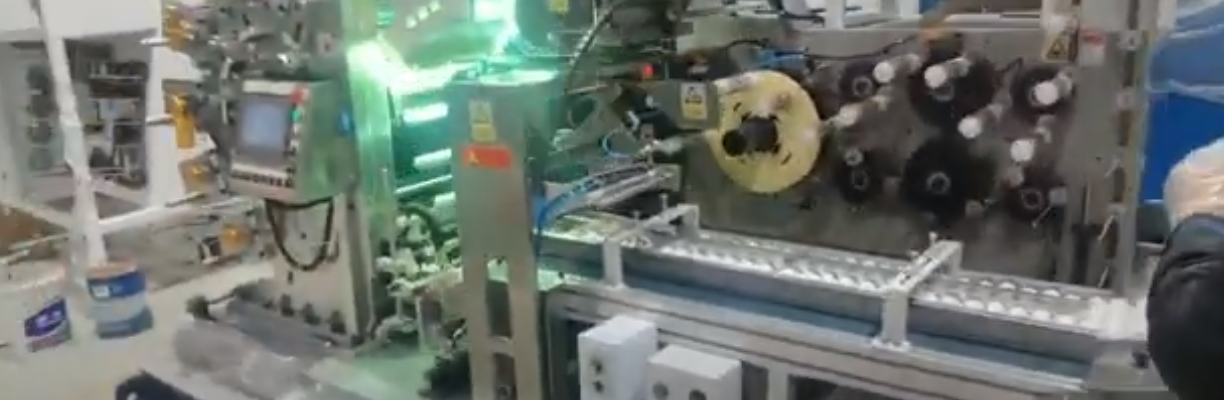

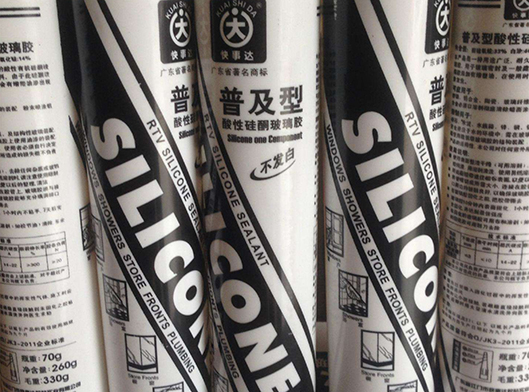

The plastic pipe printing machine adopts letterpress printing to print colorful text and patterns on the surface of plastic pipes. It can be a soft tube or a hard pipe, and it is widely used for printing facial cleanser, facial cleanser, ointment and other cosmetics, hose packaging of pharmaceutical products, and hard plastic tubes such as glass glue tubes.

Function

1.Adopting the advanced international printingtechnology.2.Designed by engine, electricity and gas.

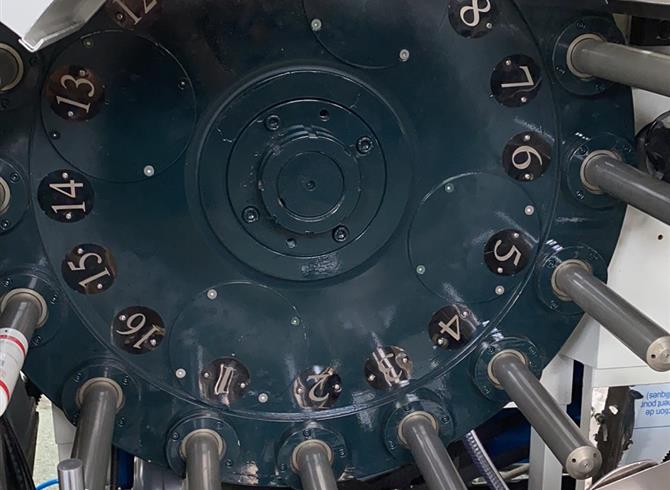

3.Adopting PLC controller, high-speed printing, fast-speed changed mold, proofread board, automatic feeding cups, collecting cups, counting and collecting the depose cups

4.Easy to operation.

5.Adopt the offset printing technology realize to print the design, word, logo and etc. On the surface of plastic containers (columnar shape).

6.Widely used to print beverage cups, yogurt cup, ice cream cup, lunch box and etc.

The main technical parameters

| Model | SMC-6T | |

| Printing diameter | mm | 60 |

| Printing height | mm | 50-200 |

| Printing speed | piece | 70~85 |

| Printing machine power | kw | 20 |

| Printing press working power | kw | 12 |

| Printing pressure | kg | 600 |

| Product height | mm | 300 |

| Working pressure | Mpa | 0.65 |

| Working color group | color | 6 |

| Printing plate thickness | mm | 0.73~0.95 |

| Printing blanket thickness | mm | 1.95 |

| Mold max diameter | mm | 70 |

| Mold min diameter | mm | 16 |

| Host uv lamp power | kw | 6kw |

| Oven uv power | KW | 4 |

| Power supply | 380V/50HZ (Can be customized according to power supply) | |

| Dimension (L×W×H) | m | 5.33X1.36X2.05 |

| Weight | T | 6 |