Brief Introduction

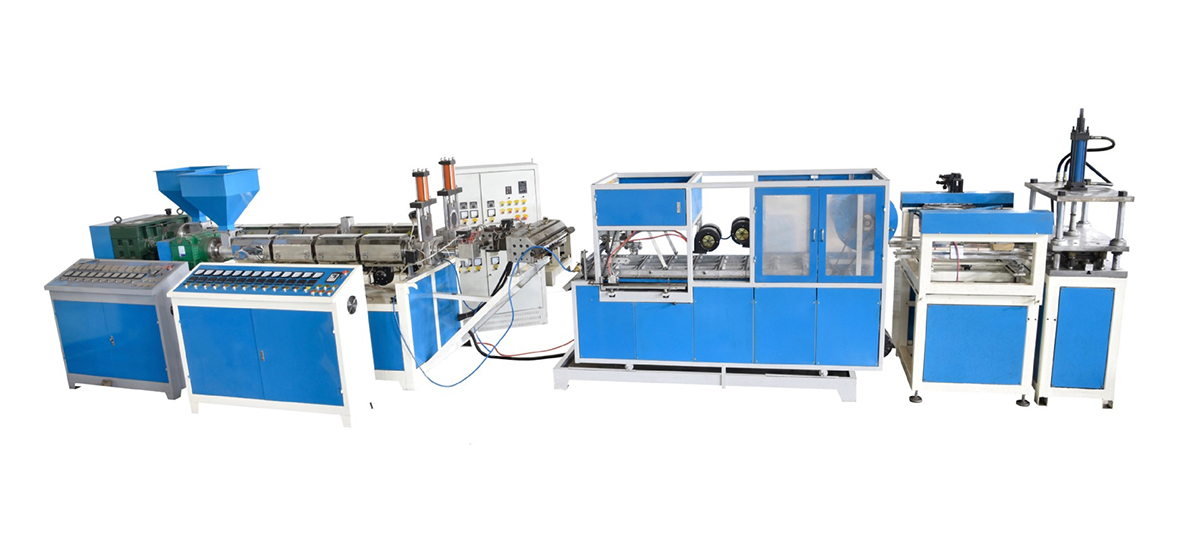

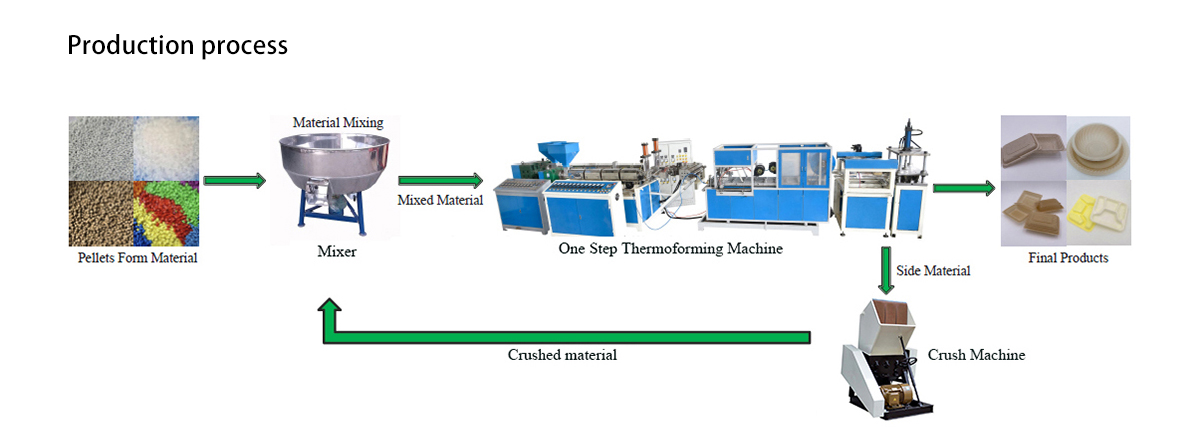

This production line is the latest type of degradable disposable plastic product molding machine, which effectively solves the problem of plastic pollution.

The machine includes an extruder, thermoforming and cutting parts. It uses raw materials such as polypropylene, calcium carbonate, talc, polylactic acid, orange straw, corn starch, wood flour, bamboo flour and other plant fibers to produce degradable cups, lunch boxes , dinner plates, plates, fast food boxes, packaging boxes, supermarket trays, biscuit boxes and other disposable products, scraps can be recycled and produced.

The main technical parameters

|

Main Screw |

90mm |

Working speed |

25-32s/min |

|

Length-to-diametre ratio of main screw |

1:32mm |

Pumping speed of vacuum pump |

70m3/h |

|

Screw rotation speed |

10~80r/min |

Vacuum limit |

2×102Pa |

|

Heating system |

65A |

Pressure of air source |

0.5~0.7mpa |

|

Extrusion output |

70kg/h |

Displacement of air source |

0.7~1m3/min |

|

Power of main motor |

30kw |

Power supply voltage |

380V50HZ |

|

Power of sucking plastic and shaping sectionunit |

1.5kw |

Weight of complete |

6T |

|

Max shaping area |

600×260㎡ |

Main engine size(mm) |

7000*1200*2000 |

|

Max shaping depth |

80mm |

The sheet width |

500mm-800mm |

|

The thickness of the sheet |

0.2mm-2.5mm |

Mold mounting dimension |

250mm-650mm |

|

The Die head Width |

0.58m-1m |

Heating Powder |

30KW |

|

Output |

100pic/min |

Vacuum Pump |

100L |