Brief Introduction

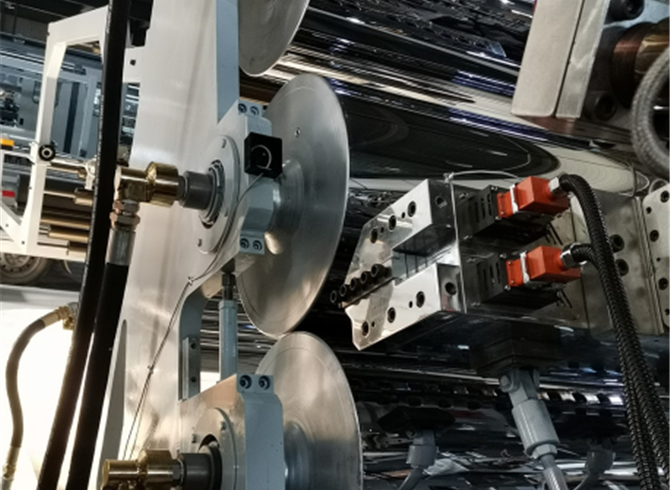

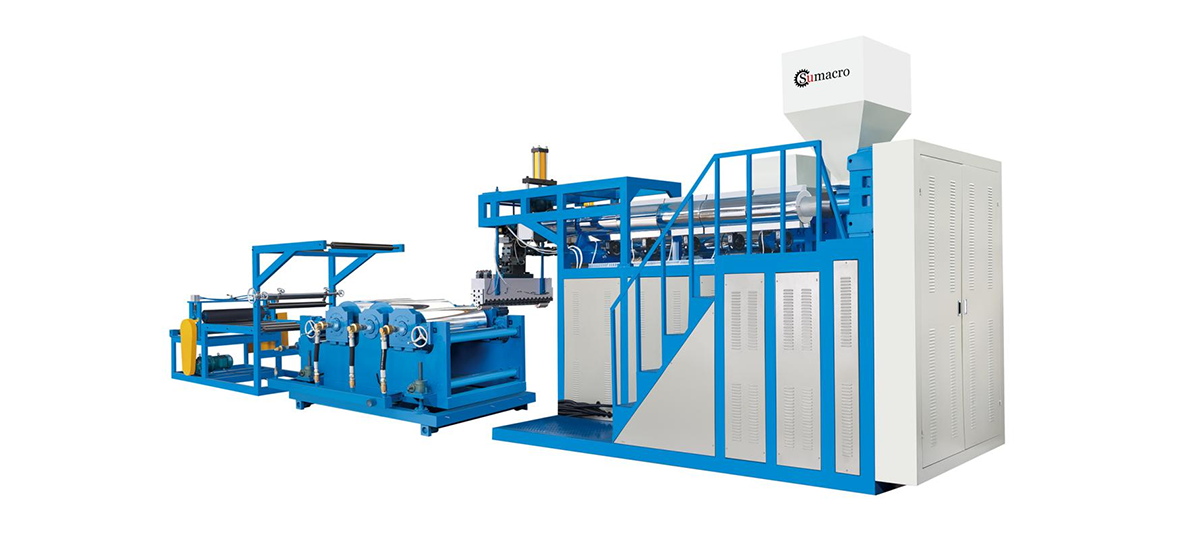

Multi-layer Sheet Extruder is composed of extrusion, calendaring, traction and rolling. The specially treated main parts are abrasion resistant, resistant to corrosion, high-temperature resistant.

Low resistance force in die head extrusion channel makes sheet thickness evenly, the spiral grooves inside the three rollers ensure efficient cooling and it is easy to change and install net changer with the hydraulic pressure unit, without stopping the machine.

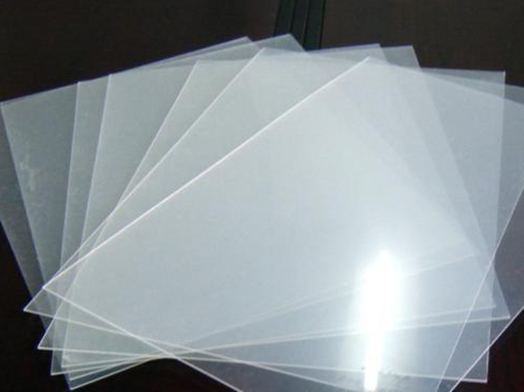

Application

The machine produces PP or PS sheets, which is used for producing plastic products , such as cups, food containers, trays, dishes, bowls, lids and etc.

The technical parameter

|

Model |

SMC105/65-900 |

SMC110/65-900 |

SMC120/80-900 |

SMC105/90/65-900 |

|

Material |

PP, PS |

PP, PS |

PP, PS |

PP, PS |

|

Max. Sheet Width |

≦780mm |

≦800mm |

≦800mm |

≦800mm |

|

Sheet Thickness |

0.25-2.5mm |

0.25-2.5mm |

0.25-2.5mm |

0.25-2.5mm |

|

Screw Diameter |

105/65 mm |

110/65 mm |

120/80 mm |

105/90/65 mm |

|

Roller Specification |

Ø400 x900 mm x3 |

Ø400 x900 mm x3 |

Ø500 x900 mm x3 |

Ø500 x900 mm x3 |

|

Layer Quantity |

<3 |

<3 |

<3 |

<3 |

|

Screw Diameter (Auxiliary Machine) |

65mm |

65mm |

80mm |

65mm |

|

Ratio of Screw L/D |

35:1 |

35:1 |

35:1 |

35:1 |

|

Ratio of Screw L/D (Auxilary Machine) |

35:1 |

35:1 |

35:1 |

35:1 |

|

Capacity |

150-180kg/h |

200-235kg/h |

320-350kg/h |

180-200kg/h |

|

Rated Power |

200kw |

220kw |

250kw |

250kw |

|

Voltage |

AC 380V,50Hz,Three-phase Four-Wire |

AC 380V,50Hz,Three-phase Four-Wire |

AC 380V,50Hz,Three-phase Four-Wire |

AC 380V,50Hz,Three-phase Four-Wire |

|

Dimension |

L14000xW2800xH2500mm |

L14000xW2800xH2500mm |

L14000xW2800xH2500mm |

L14000xW2800xH2500mm |

|

Weight |

8T |

12T |

14T |

15T |