Brief Introduction

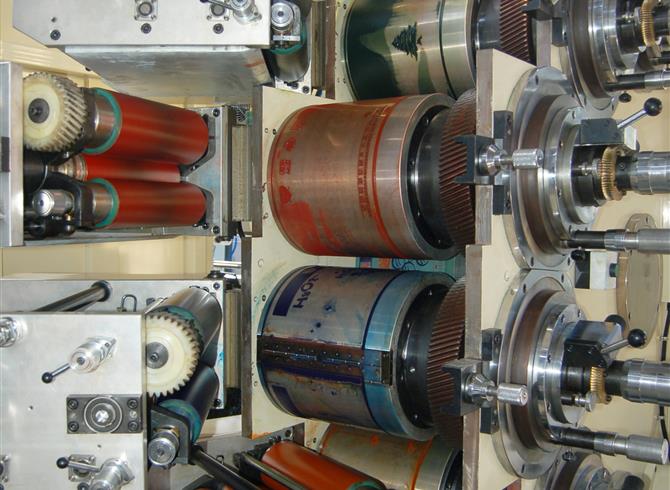

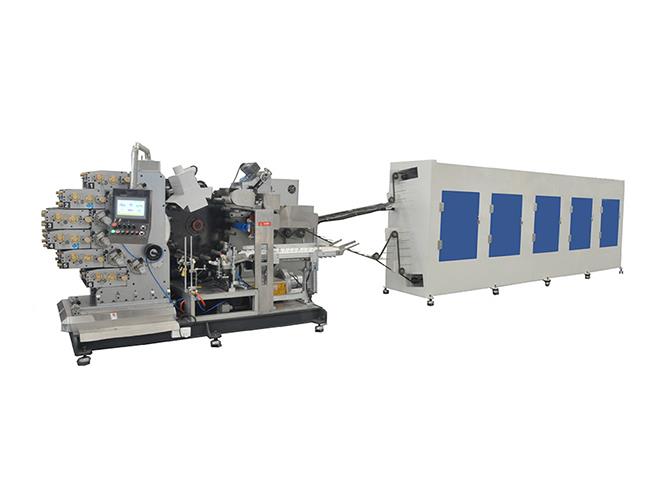

This machine adopts the letter method to use the letterpress to print double-sided color words and patterns on the surface of plastic products. It is widely used in lubricating oil barrels, inclined barrels, food special barrels, etc. Universal barrel stamping machine, plastic buckets of different sizes share a barrel mold, saving customers a lot of cost of making barrel molds.

Function

1.Adopting the advanced international printingtechnology.

2.Designed by engine, electricity and gas.

3.Adopting PLC controller, high-speed printing, fast-speed changed mold, proofread board, automatic feeding cups, collecting cups, counting and collecting the depose cups.

4.Easy to operation.

5.Adopt the offset printing technology realize to print the design, word, logo and etc. On the surface of plastic containers (columnar shape).

6.Widely used to print beverage cups, yogurt cup, ice cream cup, lunch box and etc.

The main technical parameters

| Printing object | Pail/bucket |

| Model | SMC-6P |

| Qty of color | 6 |

| Printing material | PP, PS, PET, HDPE etc. |

| Max. printing diameter(mm) | φ300 |

| Maximum bucket (bowl, tube, barrel) edge diameter (mm) | φ368 |

| Max. printing height(mm) | 300 |

| Maximum bucket (bowl, tube, barrel) height (mm) | φ380 |

| Max. printing bevel(︒) | 12 |

| Max. designed speed(pcs/min) | 200 |

| Drive system | Machanical drive |

| Printing large roller diameter | φ1000 |

| Quantity of cup molds | 6 |

| UV power(KW) | 4~8 |

| Total power(KW) | 20 |

| Power supply (single phase / three phase) | 3 phase |

| Dimensions = length * width * height (m) | 5.7*4.7*3 |

| Weight (tons) | 10 |